Achieve excellence in work management execution

Track, manage and automate work management processes to optimise methods, boost productiveness and eliminate inefficiencies

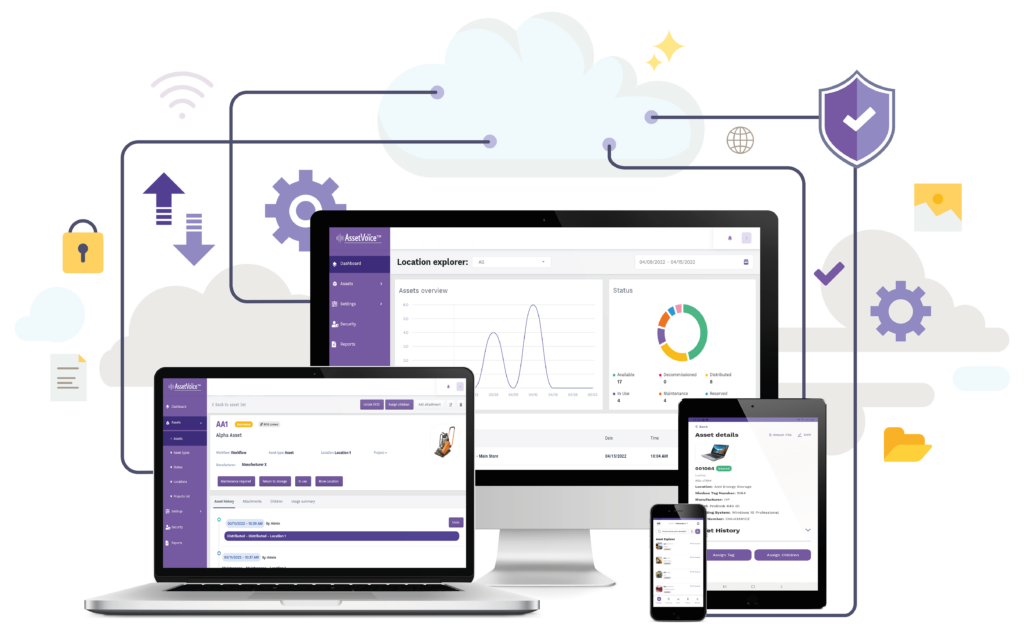

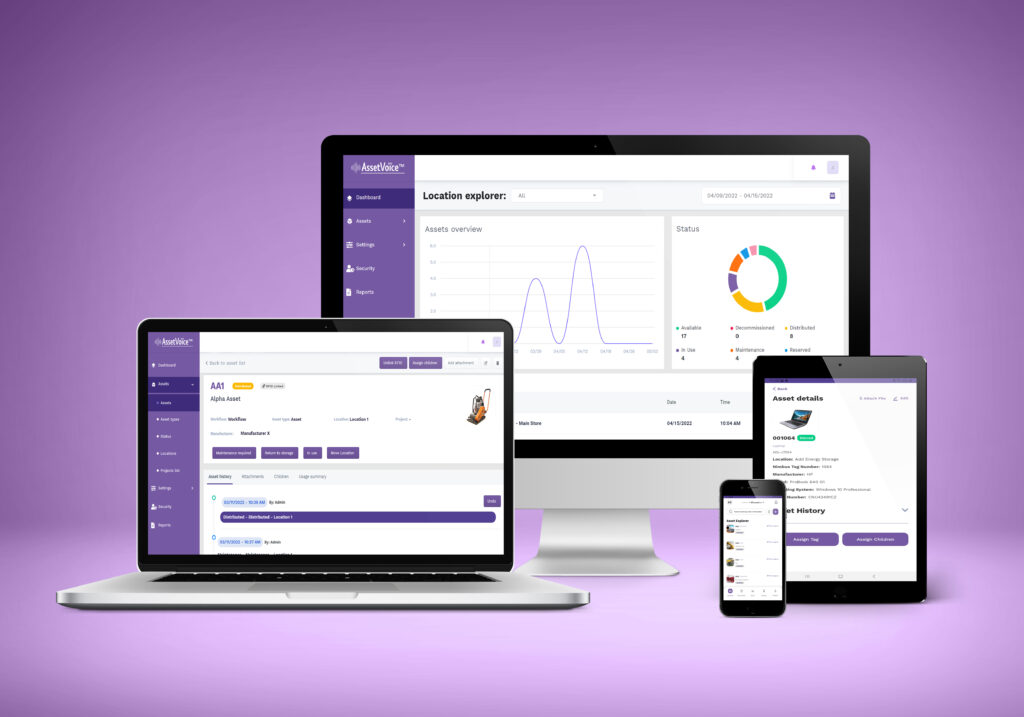

AssetVoice™ is an award-winning tracking and management of change software that uses RFID technology, sensors, and automation to monitor, manage and optimise work management processes in the most effective and efficient way possible.

Challenges you may face

- An inability to effectively prove work tasks have been completed

- Unable to accurately pinpoint inefficiencies in process with limited data or knowledge of this available

- Unable to determine resource utilisation effectively to streamline costs and methods

- Data quality has been compromised due to uncontrolled master data changes occurring or a lack of, resulting in work execution inefficiencies later on

- Difficulties in tracking adherence to processes and historical work due to volume, complexities of processes, a lack of documentation of this and the number of stakeholders involved

- Team members are unsure of exactly what they are meant to be doing, and where, resulting in increased unproductive time

How AssetVoice™ can help

- Gain full and instant visibility of your operations by tracking locations of assets, people, or status in work management processes at the click of a button

- Be notified on any condition change you want or need to know about

- Gain access to intelligence and analytics relating to your work management processes to determine opportunities to improve the process further

- Assure data integrity, standardisation, and control of master data changes through use of built in rulesets that enforce the process

- Assure adherence to processes through mandatory workflow steps and be alerted on any non-conformances or deviations

- Prove completion of work tasks by having dedicated areas for storing “proof of presence” information

- Utilise work management historical data to determine how best to boost performance, schedule work effectively and maximise resource utilisation

- Efficiently and effectively evaluate performance by having access to the data you need at your fingertips

Examples of where AssetVoice™ can add value

Plant management

- Procurement

- Site acceptance testing

- Factory acceptance testing

- Startup and commissioning

- Operations

- Maintenance

- Decommissioning

Work management

- Day-to-day work management processes (identification, planning, scheduling, execution, follow-up, analysis)

- Shutdowns and turnaround campaigns

- Muster point management

- Permit to work

- Restrictive area access management

- Maintenance and inspection workorder execution

- Overhauls

- Equipment upgrades

- 3rd party campaigns

Inventory management

- Warehouse management

- Stock replenishment and procurement

- Preservation maintenance

- Rental and serviced equipment management

Watch AssetVoice™ in action

Get in touch! By registering your interest in AssetVoice™, you can:

- Book a demo of the software

- Get more details about the software and hardware solutions

- Receive ongoing insights and advice for asset tracking and labelling initiatives

How else can AssetVoice™ be used?

Healthcare management

Rationalising costs and maximising available resources across the healthcare industry

Inventory and warehouse management

Automate warehouse and inventory processes and management of change to save money, eliminate time wastage and reduce risk.

Maintenance management

AssetVoice™ can provide real-time maintenance intelligence, notifications and alerts

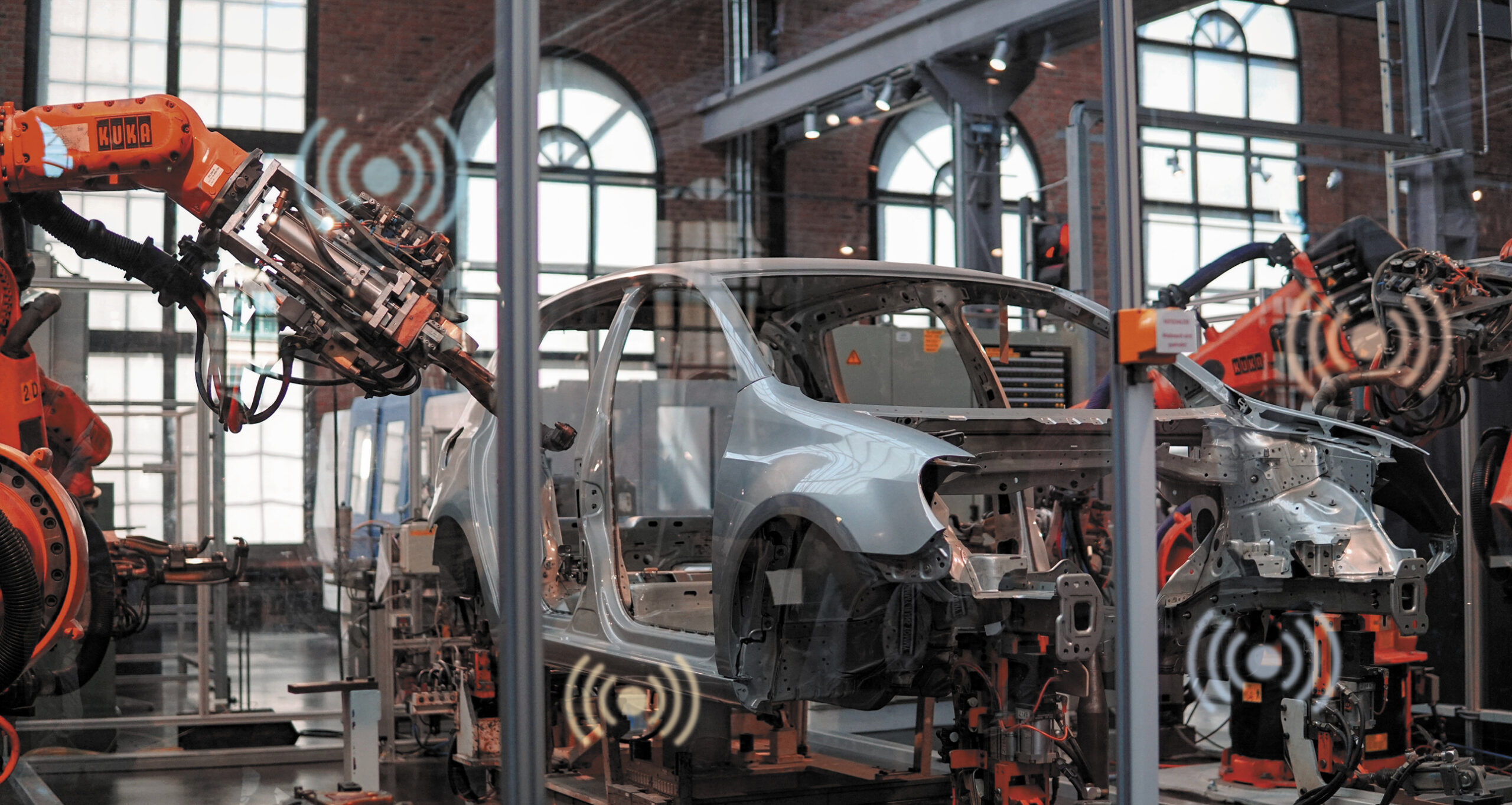

Manufacturing production and automation

Promote automation to eliminate bottlenecks and save costs in your manufacturing process

People management

Track and manage people locations and associated information throughout their journey

Plant and production

Automate processes to cut costs and maximise equipment uptime and spares availability.

Rental and service equipment control

Enabling rental and service companies to track and manage equipment throughout its journey to assure availability and boost profits.

Transportation and supply chain

Achieve unprecedented levels of transportation management and supply chain automation