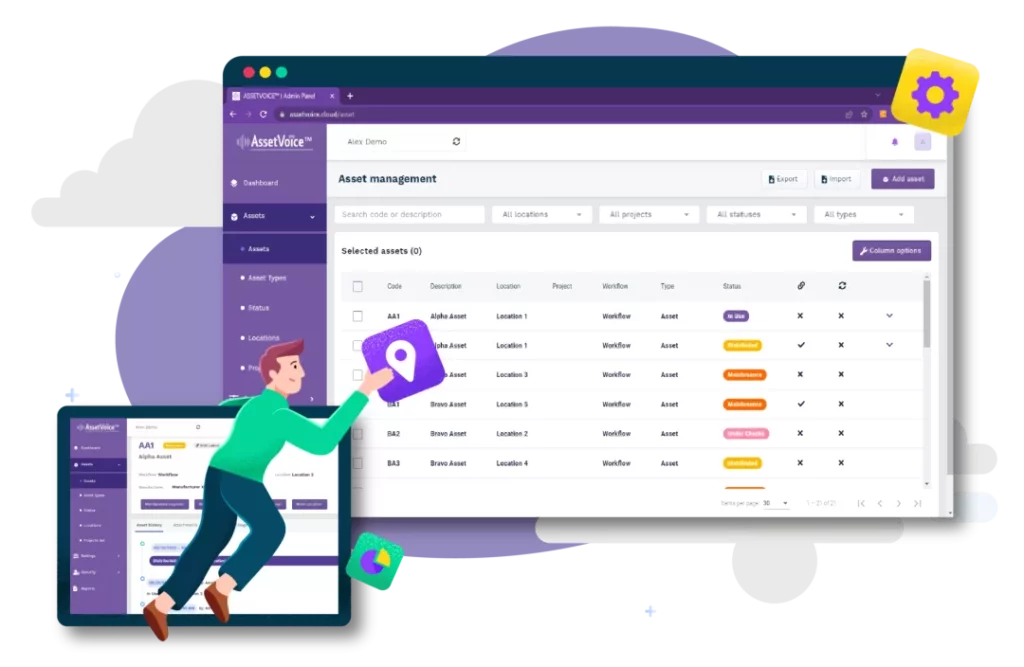

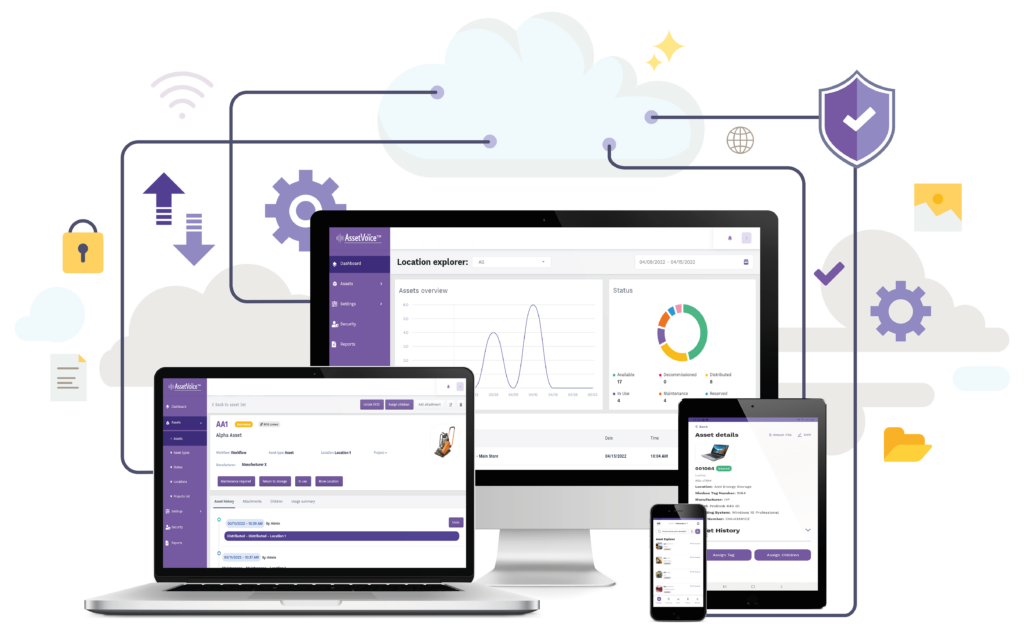

Give your assets a voice

Automated workflow and real-time asset tracking software, that cuts costs and maximises productivity

21M

Rental hours tracked to date

$102M

Rental revenue tracked across 28 countries

9K

Rental assets tracked across 50 asset types

223K

Reservation hours

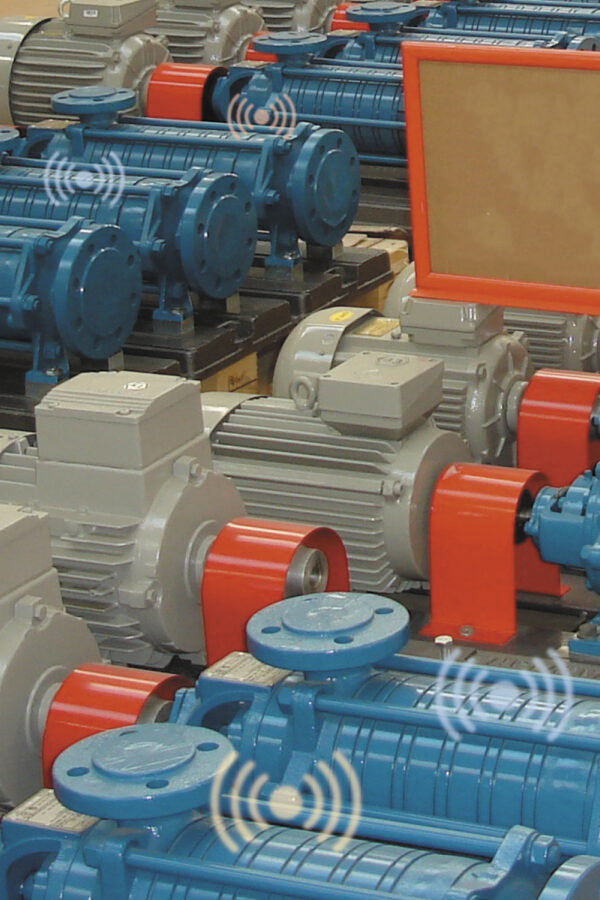

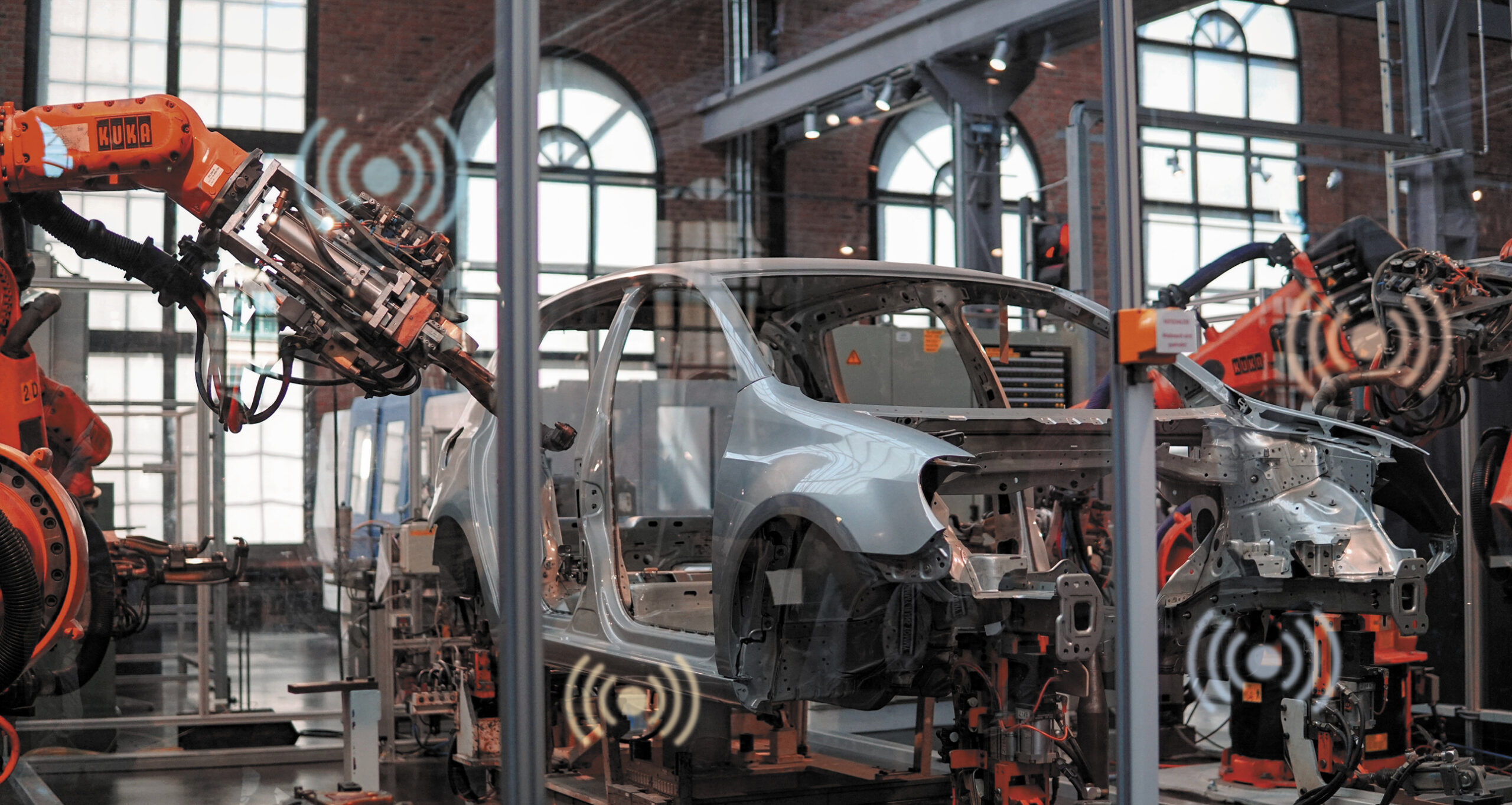

Track, monitor and manage assets in the most effective and efficient way possible

Using digital tracking technologies (RFID, NFC and barcodes), IoT and cloud services with our asset tracking and change management software, AssetVoice™ is fully customisable to your company’s specific needs – ultimately helping to reduce your workload, increase efficiencies and cut costs.

The key benefits of using AssetVoice™

- Mitigate risk through alerts and notifications about critical actions and movement

- Unlock efficiencies in business operations through access to a shared, reliable and accurate repository of assets data

- Avoid unnecessary expenditure and fines

- Gain instant access to locations and data associated with critical assets to unlock efficiencies

- Minimise time wastage searching for assets and critical data points

- Make strategic decisions with confidence

AssetVoice™ News

ABL wins NHS asset management framework agreements

We are excited to announce that we have been awarded three framework agreements with NHS Commercial Solutions for the tracking and management of critical medical equipment, assets, inventory, and the provision of associated services.

How AssetVoice™ works

Tagging

Asset existence is verified and tagged with RFID or barcode tags

Locations

Tracking locations are set up. This can include a warehouse, asset, zone, building, room, vehicle, etc

Installation

“Gate” readers and scanners are installed in the locations to capture movement

Software

Enjoy hourly auto-populated spreadsheets and progress reports to enable project benefits to be realised quicker by gaining instant access to your insights, in the format you need it in.

Integration

If required, AssetVoice™ can be linked to the CMMS or ERP utilising integration middleware technology so users can enjoy automated management of change that is cascaded through to the CMMS/ERP

Implementation

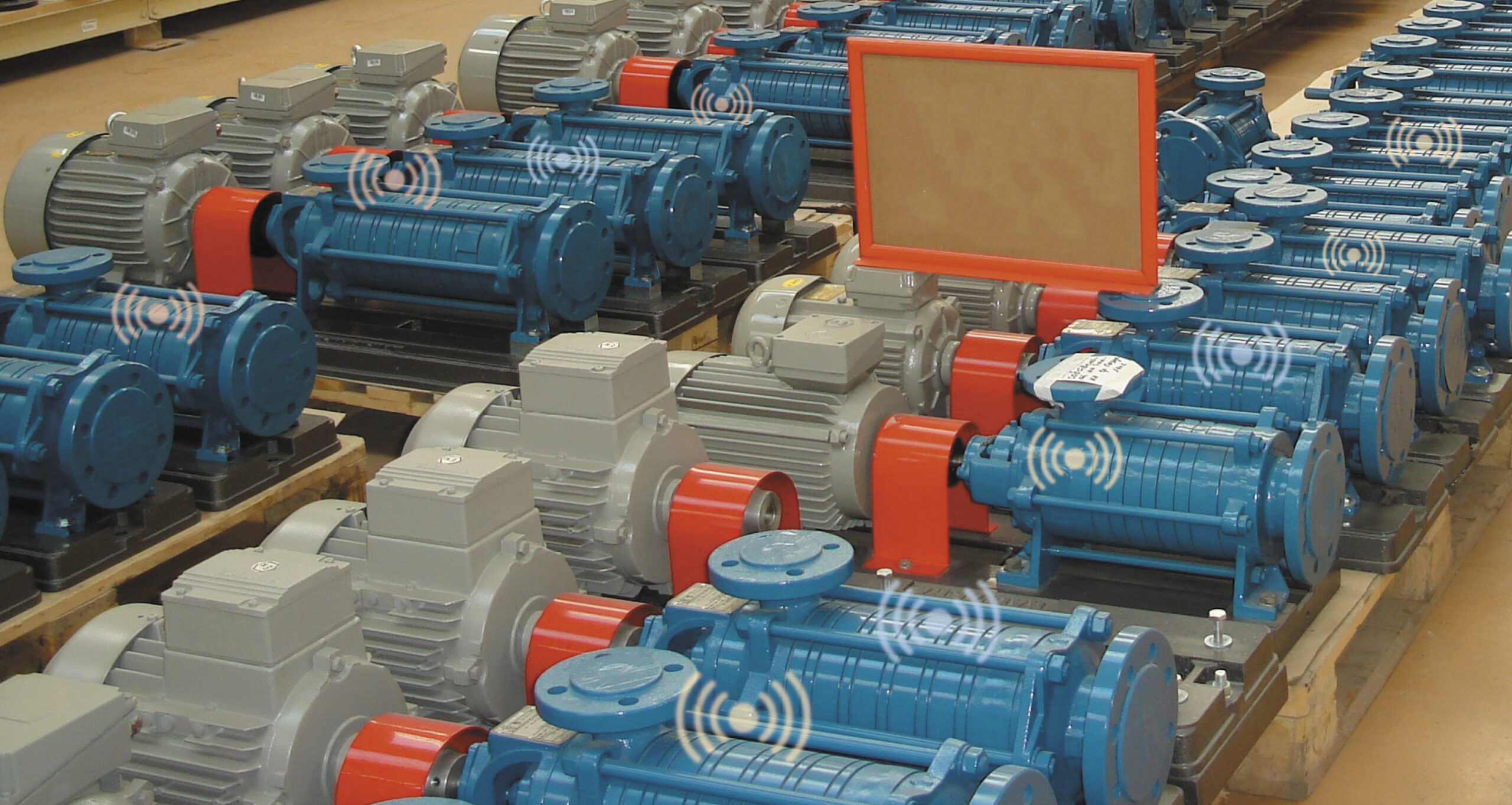

Companies can now efficiently and effectively track, monitor and manage assets throughout their lifecycle and enjoy all the associated benefits

Book a demo

Experience the software first-hand in a free demo with an AssetVoice™ expert

News

Motive Offshore Group appoints AssetVoice to digitise asset base

Leading Energy Industry Specialist Motive Offshore Group (Motive) has contracted ABL Group to automate and digitise its extensive pool of rental equipment, enabling cost-efficient support whilst improving the customer experience for offshore energy operators and their suppliers.

ABL is both an IBM Silver Business Partner and an official member of the SAP® PartnerEdge® open ecosystem.

Get in touch! By registering your interest in AssetVoice™, you can:

- Book a demo of the software

- Get more details about the software and hardware solutions

- Receive ongoing insights and advice for asset tracking and labelling initiatives